news center

recommending products

contact: mr. jin

tel: 13901575780

0512-52428686

contact: mr. zha

tel: 13913639797

0512-52422071

address: no. 59, huyi road, liantang, shanghu town, changshu city, jiangsu province.

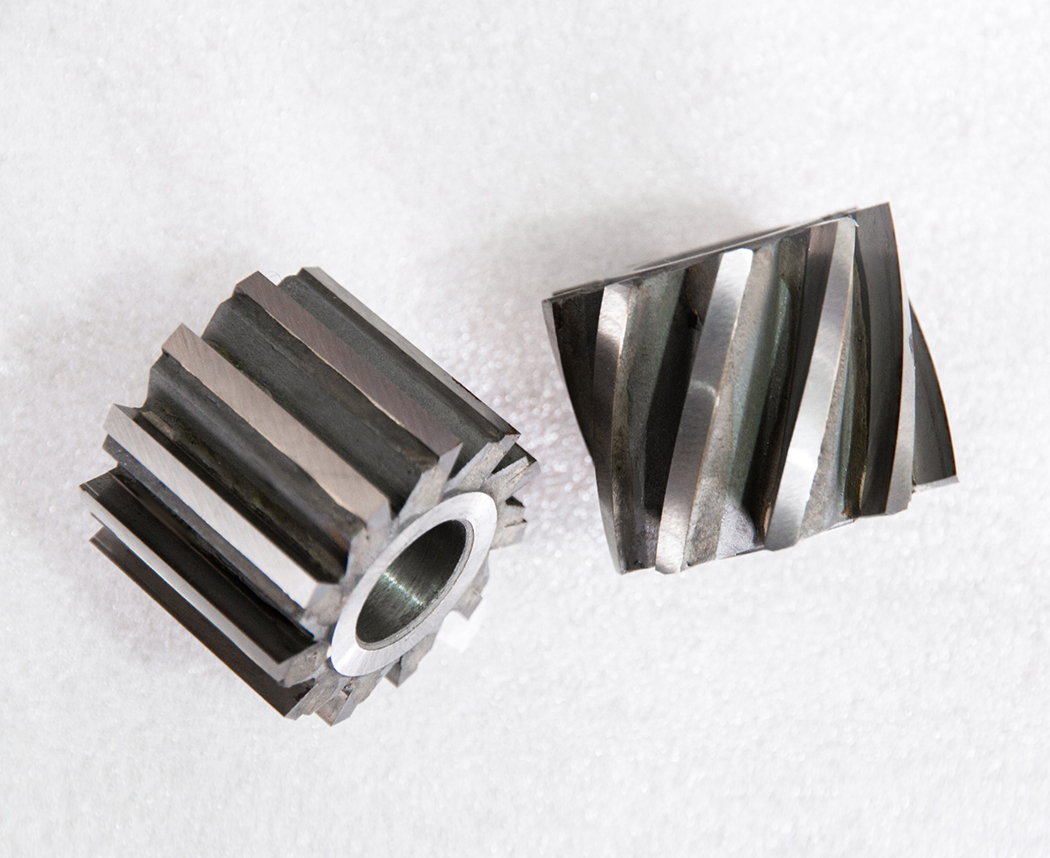

briefly introduce the tungsten steel deduplication milling cutter

tungsten steel deduplication milling cutter is a milling tool made of tungsten steel (hard alloy) as the core material, mainly used in the industrial field to "remove excess weight of workpieces and optimize weight distribution". its core features are high hardness, strong wear resistance, and adaptability to high-precision deduplication requirements.sources:k8凯发旗舰 | publishdate:2025.08.19

1. core material characteristics

substrate: the main body is tungsten steel (wc co alloy, a sintered body of tungsten carbide and cobalt), with a room temperature hardness of hrc 89-93, much higher than high-speed steel, and can handle milling of various hard or high-strength workpieces such as stainless steel, aluminum alloy, titanium alloy, etc.

coating (optional): some products will be coated with tialn, ticn and other coatings to further enhance wear resistance, high temperature resistance, and extend service life (especially suitable for high-speed cutting scenarios).

2. main functions and application scenarios

the core function is to remove excess material from the workpiece, achieving "weight reduction" and "weight balance". typical applications include:

aerospace: the lightweighting and weight reduction of aircraft engine blades and fuselage structural components require strict control of weight errors.

automotive industry: dynamic balancing and weight reduction of rotating components such as engine crankshafts and transmission gears to reduce operational vibrations.

precision machinery: partial weight reduction of core components such as molds and instruments to ensure equipment accuracy and stability.

3. key design features

blade design: spiral blades (commonly 2 or 4) are commonly used to reduce cutting resistance, lower workpiece surface roughness, and ensure a smooth cutting surface after deduplication.structural adaptation: according to the deduplication parts (such as flat surfaces, grooves, and irregular surfaces), there are various structures such as end mills, ball end mills, and forming mills to meet the deduplication shape requirements of different workpieces.

accuracy control: the machining accuracy usually reaches the level of ± 0.01mm, which is suitable for scenarios with strict weight error requirements (such as controlling the weight removal error of aviation components within the gram level).